You are here: home > Resistance Heating Wire Industrial News > Surface Area Loading of Electrical Resistance Heating element

Product (287)

- FeCrAl Alloy Wire (11)

- FeCrAl Alloy Strip (11)

- FeCrAl Alloy Mesh (11)

- Nichrome Wire (11)

- Nichrome Strip (9)

- Nichrome Mesh (10)

- Resistance Wire (131)

- Resistance Strip (20)

- Stranded Resistance Wire (2)

- Cut-Straightened Wire (20)

- Heat Resisting Mesh (20)

- Applications (19)

- Technical Data (12)

Product catalog (4)

Company Certificates (5)

Resistance Heating Wire Industrial News (30)

Applications (30)

Electrical heating elements News (6)

Credit Report

Products Index

Company Info

Heanjia Super-metals Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Beijing

Province/State: Beijing

Country/Region: China (Mainland)

Resistance Heating Wire Industrial News

Surface Area Loading of Electrical Resistance Heating element

Surface Area Loading of Electrical Resistance Heating element

Surface Area Loading of Electrical Resistance Heating element is the electric power per unit surface area. Surface loading (W) may be the electric energy per unit surface. W is greater, more warmth is going to be enhance thus less material is going to be used. But when surface loading is simply too much greater, the service existence is going to be affected as well as been oxidized or melted.

The suitable surface loading of Electrical Resistance Heating element is related with the material, size, structure, working temperature, abstraction of heat. While there is a difference on surface loading between industrial furnace and home appliance, so we can not define a general value.

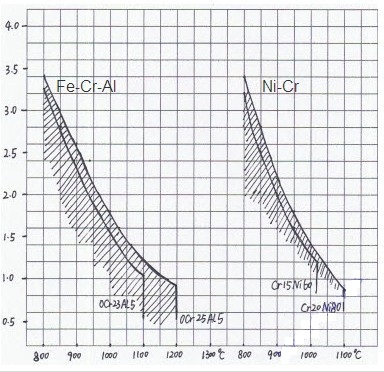

To make it much easier to design the industrial furnace, We here attach the below figure shows the relation between furnace temperature and element surface loading of Electrical Resistance Heating element. This is from many years' experience, including FeCrAl 0Cr23Al5, 0Cr25Al5 and NiChrome 80/20 and NiChrome 60/15.

Normally, strip heating elements has a higher surface loading than wire heating elements.

Normally, strip heating elements has a higher surface loading than wire heating elements.

Electric heating appliance no matter for industry or home, there are three kinds of methods to install the resistance heating wire. First is "embedded". The heating element is embedded in insulation materials. The heating element can not be moved or out of shape, and can not be easily oxidized neither. The surface loading will be 1-80W/cm2 under this situation. Second is "supporting". The heating coil is put on the surface or groove of fire proof material. The heating element can be stretched and distorted in shape. At this environment, its surface loading is 1-10 W/cm2. The third method is "hanging". The heating element is hanging between insulation supporting place. The heating element can be out of shape because of its own weight. The surface loading is 3-15 W/cm2.

Pre Page:

Nickel chromium alloy resistance heating...

Next Page:

Electrical Resistance Heating...

.gif)